During the passivating contact workshop in Eindhoven earlier this year more than 80 people enjoyed several in-depth presentations and discussions on this hot topic in crystalline silicon PV research. Since the PV conference low season / summer break has started now, this is a great time to look back at the workshop! First of all, let’s have look at the various types of responses that were handed in by the attendants after having participated in the workshop to give you an idea of the audience and their general opinion about the workshop.

Responses to the workshop:

Students Professionals (> 5 years) Postdocs Professionals (< 5 years)22 36.1% 20 32.8% 10 16.4% 9 14.8%

The workshop was well presented by the speakers

The workshop met my needs

Enough time was allocated to cover each theme

The workshop was well organized

I liked the format of the workshop

A few quotes:

Very well prepared presentations.

Do it again!

Thanks for organizing!

More discussion on challenges towards industrial challenges and metallization would be great.

Given the positive feedback on the workshop as outlined above, it seemed like a good idea to give you a basic overview of the content of the workshop. Therefore, a series of three posts will appear on this weblog in the following weeks – one new post every week – and you have already found the first one of these personal perspectives on the presentations given by the invited speakers now! First of all, in this blog post I will summarize and interpret the first two of the six contributed talks given at the workshop given by Prof. Dr. Wim Sinke (Energy Research Centre of the Netherlands / University of Amsterdam) and Dr. Lars Korte (Helmholtz-Zentrum Berlin).

(*) The write-up in this post is my personal reflection of the speakers’ presentations. The speakers have seen the text and given their permission to use their visual materials. Special thanks go to Dr. Ingrid Romijn and Dr. Paula Bronsveld for their notes taken during the presentations!

Prof. Dr. Wim Sinke (Energy Research Centre of the Netherlands / University of Amsterdam):

“Si PV technology development in new perspective” (*)

Crystalline silicon (c-Si) solar cells have seen great successes over the past decades, characterized by huge reductions in cost and increases in efficiency. However, the research on crystalline silicon cell technology seems to be victim of its own success, as the c-Si technology is taken for granted now by some. In particular, the sentiment at policy makers seems to be that the technology is “finished”, since it is available in large quantities for low prices, so why would we bother with research?

This view is far from the truth, as many things on cell and module level can and need to be optimized and improved further, towards higher efficiencies, more cost-effective processes, and innovative solutions. As a long term goal, prices need to go down below 0.01 €/kWh and it is one of the jobs of the research community to convince the policy and decision makers that research on c-Si photovoltaics (PV) is still very relevant (and that we are doing a good job at it!).

To convey this message and to structure the different research efforts in the PV field efficiently, a good storyline is needed. This can be done by updating the generations view of PV technologies that has been used for many years.

Previously – approximately up until 10 years ago – there was a view on PV research categorized in three generations. In this view, the c-Si technology made up the first generation of PV with a relatively high efficiency, but also high costs per m2. The second generation, consisting of thin film technologies such as hydrogenated amorphous silicon (a-Si:H) and copper indium gallium selenide (CIGS), would offer PV at significantly lower cost per m2, leading to lower cost per Watt peak of module power. Finally, there was a third generation of PV, which included a range of materials and device concepts that had the promise to offer very high efficiencies at (ultimately) low cost per Watt peak.

Although this picture of PV generations has had its value in the past, it no longer makes sense nowadays. For instance, in the 1990s, c-Si was predicted to lose its dominant market share by the year 2000, but things have developed very differently. c-Si technology has seen a tremendous cost reduction since then, which means that it is now very competitive in terms of costs and it offers higher efficiencies at costs similar to thin film technologies. The c-Si PV industry seems to stick to evolutionary rather revolutionary developments, which has resulted in a gradual efficiency increase from 15% to 23% in the 2000-2018 period. Since the efficiency limit (29.4%) has not been reached yet, there is still room for further improvement from the 26.7% solar cell efficiency lab record and the 22-24% state-of-the-art module efficiencies that can currently be reached in production environments.

It is expected that the gap between the lab record and efficiencies achieved in industrial environments will diminish, meaning that 25-26% efficiency will be reached for commercial cells in the next few years at low costs and high throughput. The next step in industry after that achievement is likely to move to hybrid tandems.

c-Si may well form the basis of future PV developments. Based on that idea it is possible to formulate a new generations view that captures a gradual evolution of technology in 4 steps:

- Solar cells limited by the extrinsic c-Si material quality. Improvements of the base material are currently ongoing in industry to address issues such as light-induced degradation, quality differences between n- and p-type wafers and between mono and multi c-Si.

- Solar cells limited by surface and interface quality. A shift in research focus to surface passivation and passivating contacts is expected when the bulk quality has reached a high level. This is illustrated by the already increasing R&D efforts aimed for instance at heterojunction solar cells and poly-Si contacts, both in academia and in industry.

- Solar cells limited by the intrinsic c-Si properties. In this Auger recombination limited case, a shift to thinner wafers may be the next step to achieve higher efficiencies, so light trapping becomes more important. The industry is approaching this situation, while academic R&D on light trapping has already been going for a longer time.

- Solar cells limited by the c-Si bandgap. To eventually exceed the Shockley-Queisser limit, a shift to tandem cells is expected. While there are signs that the industry is starting to work on this, academic research in this field is already enabling higher efficiencies for the future.

To enable the PV evolution as outlined above, the research community is faced with many challenges still, as only the surface has been scratched for some of these topics. This means that there is still plenty of room for improvements in the future, thus motivating the need for further research. In the bigger picture beyond today’s power generation this is very much needed when aiming to make solar energy the pillar under the transition towards more renewable energy. When considering that energy generation on the TW scale per year is required, the growth in all fields of renewable energy research, including PV, needs to be tremendous.

Dr. Lars Korte (Helmholtz-Zentrum Berlin):

“Introduction to passivating contacts” (*)

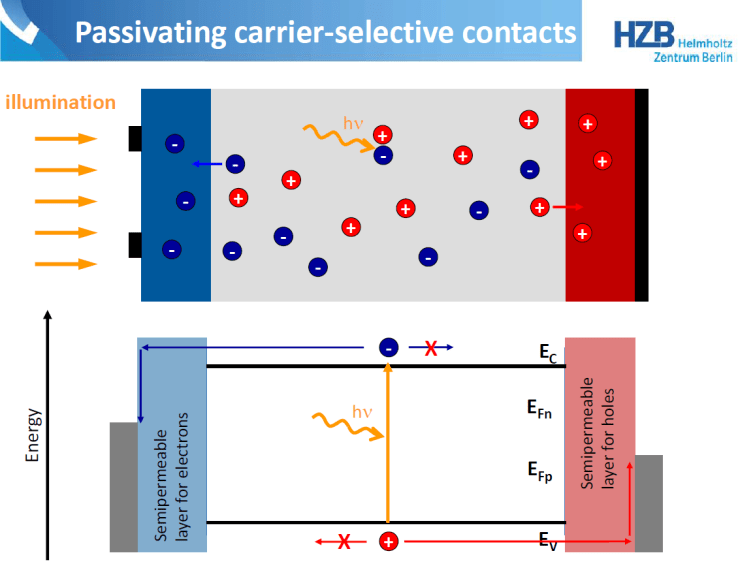

Passivating contacts have two primary functions: to passivate the c-Si surface and to act as carrier-selective membranes to conduct either electrons or holes. In other words, carrier selectivity can be realized when the current flow for one carrier type is very large, while the current flow for the opposite charge carrier type is very small.

This can be better understood when considering the dependence of the electron and hole currents on the conductivity for electrons and holes as well as the gradients in the quasi Fermi levels for electrons and holes:

where Je and Jh represent the current densities for electrons and holes, σe and σh denote the conductivities for electrons and holes, and ∇EF,n and ∇EF,p correspond to the gradients in the Fermi level for electrons and holes, respectively. Furthermore, it is known that the conductivity σ depends on the charge carrier concentration n and the carrier mobility μ:

![]()

The charge carrier selectivity can therefore be manipulated through the charge carrier concentration or the mobility for electrons and holes. The mobility cannot be varied so easily in a wide variety of materials, while that is possible for the carrier concentration, making this a key parameter in controlling carrier selectivity [1].

The classical approach to achieve selectivity is found in solar cells based on diffused p/n junctions, in which the conductivity can be manipulated by doping. A more novel approach that is applied in heterojunction solar cells is to make use of a band edge that can be offset by bringing a material with a different (wider) bandgap in contact with c-Si, such as a-Si:H. After this c-Si/a-Si:H interface is formed, a re-equilibration of the charges near the c-Si/a-Si:H interface will take place, which results in a shift in the Fermi level. When electrons are the minority carriers in the contact, a heterojunction with a valence band offset reduces the minority carrier concentration in the contact much more than a diffused junction without band offset.

The principle of passivating contacts (sometimes also referred to as carrier-selective contacts) can be conveniently explained using silicon heterojunction (SHJ) solar cell technology as a starting point:

- Undoped (or intrinsic) a-Si:H layers are used to provide optimal chemical passivation to the c-Si surface, thus lowering the interface defect density. Research is currently ongoing to replace the a-Si:H layer, which induces significant absorption losses, by a more transparent type of interlayer, such as SiO2.

- Doped a-Si:H layers deposited on top of the intrinsic a-Si:H layers induce either hole (p+-a-Si:H) or electron (n+-a-Si:H) selectivity. Typically, very thin a-Si:H layers are used to prevent too high parasitic absorption.

- Since the passivating contacts do not provide sufficient lateral conductivity here, transparent conductive oxides (TCO) are deposited on top of the doped a-Si:H layers to achieve this. Research efforts are ongoing to use more transparent (and potentially thinner) TCO layers to mitigate optical losses.

Apart from a-Si:H, other materials can be used in heterojunctions as well to form carrier-selective contacts and many of these materials have been investigated already in the organic photovoltaic community [2]. Theoretically, high open circuit voltages can be reached when using materials with appropriate work functions. An electron-selective contact on c-Si can be formed with materials that have a work function of 4.1 eV (which is the electron affinity of silicon) or less, such as TiO2. Materials that have a work function of 5.2 eV (corresponding to the sum of the c-Si bandgap and electron affinity, also known as the ionization potential) or more, such as MoO3 [3,4,5], V2O5 [6], and WO3 [7], are candidate hole-selective contacts on c-Si.

In practice, it is difficult to achieve high Voc levels due to Fermi level pinning, which often takes place. This limits the changes in band bending that can be realized to only a few tenths of eV. Also, it should be noted that when discussing the effects of band offsets and different work functions on the amount of band bending in the silicon, the vacuum potential is typically taken as the reference energy level. This method – known as Anderson’s rule [8] – discards interface properties that affect the band offsets [9] and the impact that the exact composition of each material has on band offsets and work functions. Therefore, vacuum-referenced energy levels cannot be used to accurately evaluate the amount of band bending in the silicon, but they are still useful in estimating the amount of band bending [10].

Another important factor in achieving high Voc is the passivation quality, as characterized by the interface defect density (Dit) and fixed charge density (Qf), which affect the chemical and field-effect passivation quality, respectively. Very low Dit values (below 1010 cm-2) are required to ensure that recombination no longer plays a role, so controlling the passivation of the interface is crucial [11,12], in addition to effects induced by the band offsets [9].

References

[1] U. Würfel et al., IEEE J. Photovolt. 5 (2015) 461. DOI: 10.1109/JPHOTOV.2014.2363550

[2] M.T. Greiner et al., Nature Mater. 11 (2012) 76. DOI: 10.1038/nmat3159

[3] C. Battaglia et al., Nano Lett. 14 (2014) 967. DOI: 10.1021/nl404389u

[4] C. Battaglia et al., Appl. Phys. Lett. 104 (2014) 113902. DOI: 10.1063/1.4868880

[5] J. Geissbühler et al., Appl. Phys. Lett. 107 (2015) 081601. DOI: 10.1063/1.4928747

[6] L.G. Gerling et al., Sol. Energy Mater. Sol. Cells 145 (2016) 109. DOI: 10.1016/j.solmat.2015.08.028

[7] M. Bivour et al., Sol. Energy Mater. Sol. Cells 142 (2015) 34. DOI: 10.1016/j.solmat.2015.05.031

[8] R.L. Anderson, IBM J. Res. Develop. 4 (1960) 283. DOI: 10.1147/rd.43.0283

[9] J. Tersoff, Phys. Rev. B 30 (1984) 4874. DOI: 10.1103/PhysRevB.30.4874

[10] J. Melskens et al., IEEE J. Photovolt. 8 (2018) 373. DOI: 10.1109/JPHOTOV.2018.2797106

[11] C. Leendertz et al., Appl. Phys. Lett. 98 (2011) 202108. DOI: 10.1063/1.3590254

[12] R. Rößler et al., J. Appl. Phys. 113 (2013) 144513. DOI: 10.1063/1.4799042

Leave a Reply